A modern steel plant in the central United States is a producer of custom rolled steel & rebar. The plant produces steel from recycled scrap metal received by rail cars. Once received, the scrap metal is sorted into various types of metal. Scrap metal is melted using electric arc furnaces (EAFs). EAFs require very high power to melt the scrap metal before it is prepared for a series of processes for converting it into other steel-based products.

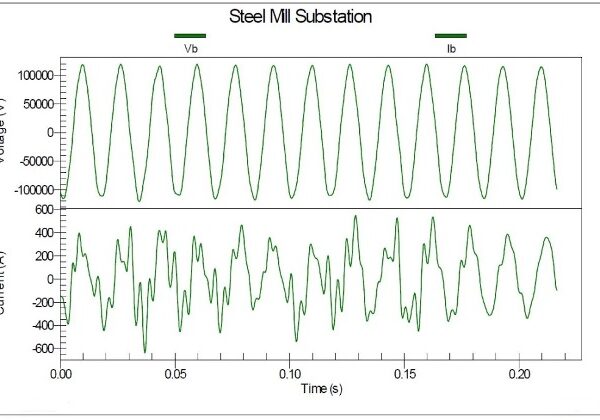

Because the melting process uses an electric arc to melt the metal at very high temperatures, a high current is required in the arc. The scrap metal is part of the circuit for the EAF. Because of irregularities in the metal & other factors, the current is not stable & fluctuates significantly during the melting process. This high level of fluctuating current causes the voltage to also experience high levels of fluctuations. Figure 1 illustrates how the fluctuating current & voltage waveforms look during a melting process.

The voltage in Figure 1 contains fluctuations. Looking closely at voltage, one can see the power frequency doesn’t vary that much, but the maxima & minima are not constant. Because the voltage is high, these fluctuations are significant. The voltage is also distorted to some extent.

However, the current is very erratic. It does contain a lot of 60-Hertz power, and it also contains some power at frequencies below 60 Hertz & at frequencies above 60 Hertz. If one were to calculate the harmonic spectrum of the voltage & current, one would see exactly the other frequencies where the voltage & current are located besides the 60-Hertz fundamental component.

Because some of the high levels of fluctuating current are low frequency (less than 60 Hertz), some of the voltage fluctuations are also low frequency between 2 & 20 Hertz. The nature of the low frequency current passes through the plant’s power system & back up into the utility’s substation. This steel plant was powered by a pair of 230-kV transmission lines derived from a 500-kV substation where three utility’s systems are tied together. (In this steel plant, the EAF was powered by a 35-kV bus derived from the incoming 230-kV supply voltage to the plant.)

The voltage at the substation bus also fluctuates at the same frequency. The fluctuations also flow back up onto the substation’s transmission bus. (Steel plants are fed by transmission voltages because they require very high levels of power to operate. The EAFs consume most of the power.) When the substation’s primary transmission bus voltage fluctuates, the fluctuations propagate onto the transmission system & appear at other substation primary voltages. These fluctuations pass down through substation transformers & cause voltages on utility distribution systems downstream to fluctuate. Such fluctuations are passed along to other customers & cause them power quality problems as well.

Fluctuating voltages cause customers’ lighting systems to flicker severely. Flickering lights can cause end users to have headaches & irritates their vision. Because voltage flicker can easily become a widespread problem for utility customers, the most effective method of resolving flicker problems is to filter out the fluctuating voltage at the source of the flicker—in this case, at the steel mill. (The EAF is the source of the flicker here.) Although this method is most effective, it is extremely expensive because of the high supply voltage required to operate EAFs & steel mills.

The power system design at this steel mill did include an advanced (i.e., electronic based) active static var compensator (SVC). SVCs are typically used to filter out fluctuating voltages caused by arc furnaces. Fluctuating voltages can be caused by other large loads that also draw large fluctuating currents. Such loads include large cranes, for example. Depending on the size of a crane, it can also draw high levels of current when it’s operated (i.e., when it’s picking something up.) One problem with the application of the SVC at this steel mill was exposure of the main 35-kV bus to physical objects entering the plant’s internal substation. The same problem existed on the 230-kV bus after the power was delivered to the plant by the local utility.

With the plant already experiencing a series of internal power quality problems, one of which is discussed in Case Study No. 4, the last thing they needed right now was another problem affecting their quality of voltage or current. One day, PBE Engineers received a call from the head electrical engineer at the plant. The plant suddenly experienced a complete outage which stopped all melting & milling processes at the plant.

With temporary power quality monitors already in place to address the other power quality problem, remote examination of the voltage by PBE indicated a series of unusual looking faults that occurred on the 230-kV bus just prior to the outage. These faults only occurred withing a short window (less than one second) but were cleared. PBE was not sure what had caused these faults on the main bus but suspected the problem was caused by animals interfering with the lines or bus. PBE asked the plant’s engineer to go to the main substation & see if there was any evidence of outside objects such as animals that had interfered with the bus. (There were no trees near the plant’s substation, so trees were ruled out as the cause of the unusual looking faults.)

Upon visual inspection of the plant’s main substation, the engineer found many dead large birds on the ground beneath the 230-kV bus work inside the substation fence. These birds were identified to be crows. (There were many acres of corn fields near the plant.) The engineer took closeup photographs of the main 230-kV bus & sent them to PBE for additional examination. Upon examination of the photos, PBE determined that the interfering objects were indeed the birds as some small fragments of feathers were seen on parts of the bus. The bus work had no bird guards on it. Because the 230-kV transmission line was several miles from the plant’s main substation & could have experienced other interfering objects (e.g., trees), verification that the birds interfered with the plant’s 230-kV bus work was needed to ensure that no other objects had interfered with the 230-kV supply.

After this outage incident, PBE recommended that the steel plant install bird guards on the 230-kV bus work inside the plant’s substation as well as on the plant’s 35-kV substation bus work as well.

Want to learn more about PQ & keep up with new PQ problems facing customer facilities, plus much more? Subscribe to one of PBE Engineers’ newsletters that’s free!